First Approach Adven's boiler, commissioned in 2023, experienced significant challenges related to...

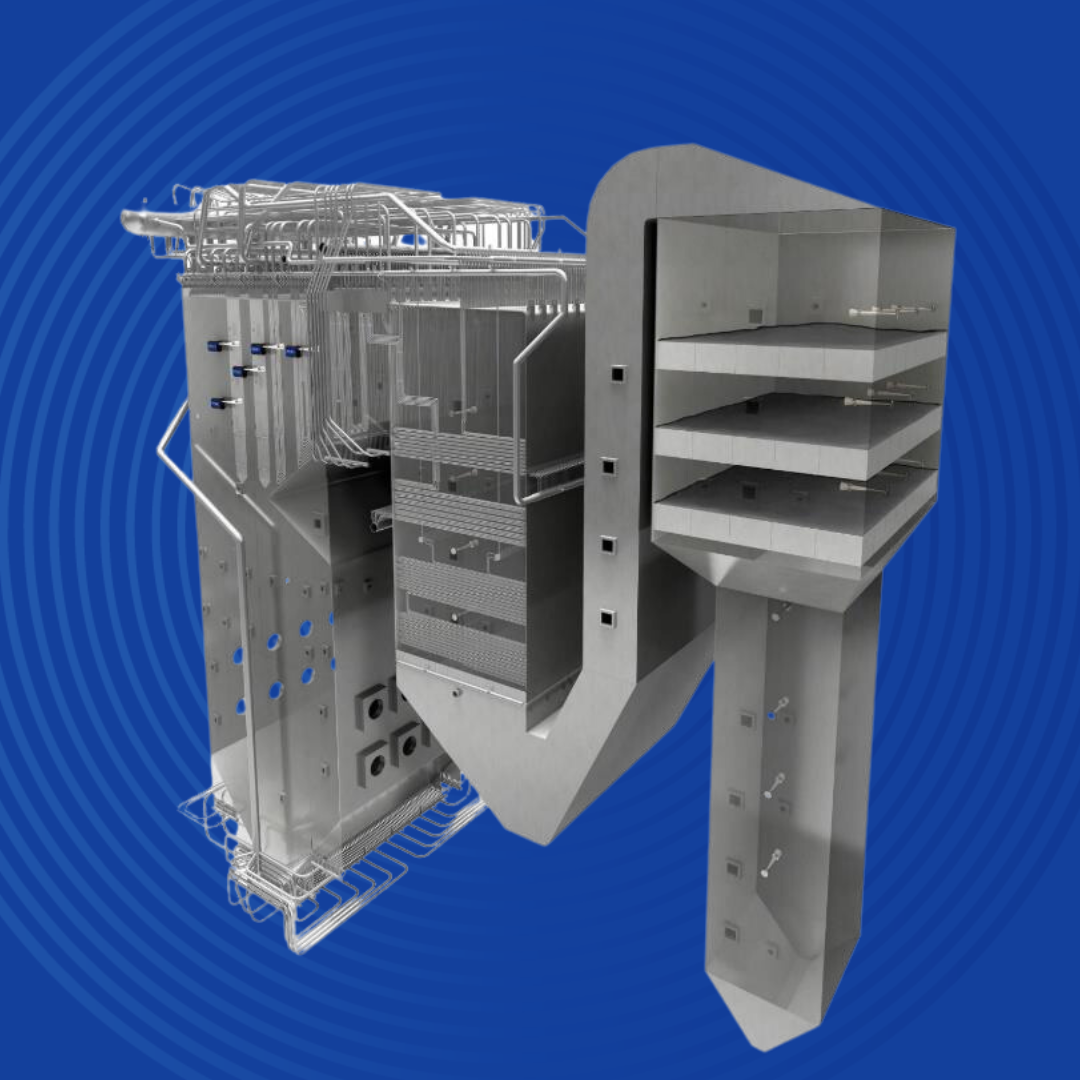

Our portfolio contains three pressurized air-driven acoustic cleaner models, named according to their basic frequencies (NI60 = 60 Hz, NI100 = 100 Hz, NI250 = 250 Hz). Together with the NCSD® they form the basis for our acoustic cleaning system engineering.

In principle, the lower frequency cleaners provide more efficient cleaning results. However, number of other factors must be taken into account to choose the best overall cleaning solution. To name a few, these include the amount and composition of ash, cleaning temperature, noise limits, and dimensions of the space to be cleaned. For different space utilization, all models have a straight and a 90-degree curved horn profile version.

Whatever the application, the customers don’t have to worry about what cleaners to choose. We always customize our systems to best suit our customers’ needs with over 30 years of experience.

The NIRAFON® system can be used in combination

with existing cleaning system

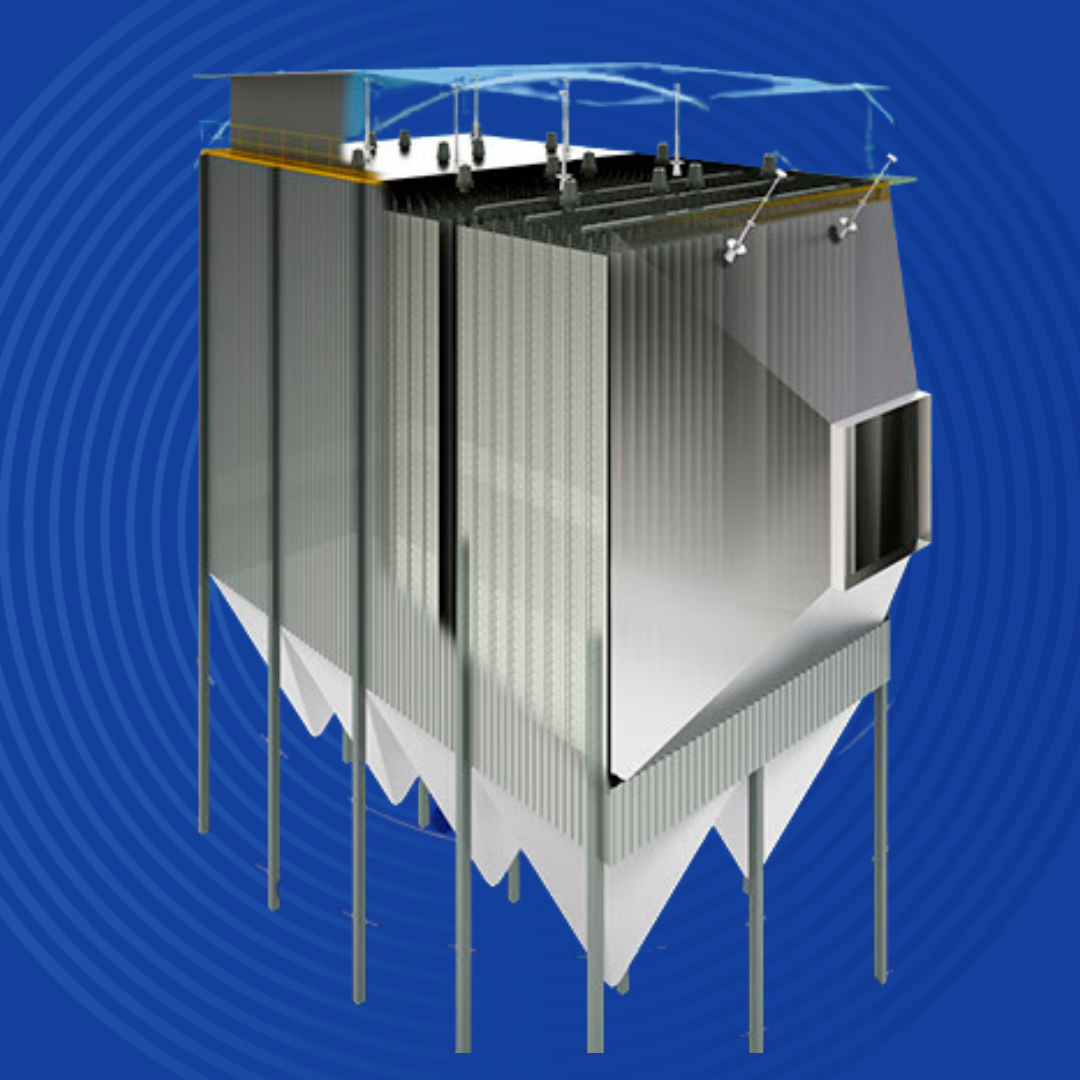

ESP-eliminating the weaknesses of rappers

Remember:

Baghouse- overcoming compressed air pulse systems

Keeping SCR systems clean

Prevent the catalysts become clogged and break down

Eliminate the risk of plant downtime

Ensure the correct operation of SCR systems, while maintaining high plant efficiency

Heat transfer and other surfaces to be cleaned stay permanently clean and the process can continue without interruptions, rendering expensive shut-downs unnecessary.

Acoustic cleaning drastically reduces the use of water at the plant, without causing corrosion or erosion. Sound won’t make any damage to structures.

The acoustic cleaners require little space, the maintenance and operating costs are low. The refund time of the system is short.

A tailor-made plan is always drawn up by NIRAFON Oy according to the application specific needs.